Are you ready to take your feeding system to the next level?

Automate Your Feeding System

By simply turning dials on your mill and flipping a switch, you can start and stop augers that bring grains and other commodities from your storage bins. You can just as easily reverse the process and send completed feed to your storage bins.

Centralize Your Feeding System

Create a livestock feed preparation hub. Mix, grind and convey cereal grains and required supplements for the dietary needs of your livestock— all in one central location on your farm.

Improve Efficiency on Your Farm

We know how important time and money are to farmers like you. Cut your overall feeding costs by mixing your own blends of feed on your farm. Save time and energy by simplifying your daily feeding routine.

Our Products

GRIND-RITE

- Hammermill

- Stainless steel

- Built to last

- 18” diameter screen

- 6” or 3 ½” base auger

- Electric powered in horsepower required

- Magnetic inlet protection

MIXMILL/FARMATIC

- Stainless steel hammermill

- 5 compartment proportioner

- Screens are easily changed

- Installation and service available

- We provide service to all Farmatic Mills

HAMMERMILL CONSUMABLES

- Screens 18” 16” & 14”

- Screens hole sizes 1/16”-3/4”

- Screens fit:

– Farmatic

– Mixmill D

– Farm King18″

– Valmetal - Hammers fit:

– Mix mill

– Farmatic - Hubs can be changed on competition brand

to use our hammers - Stainless steel top compartments

- Stainless steel hoppers for above mills

- Manufactured by Nu-Matic Systems Inc.

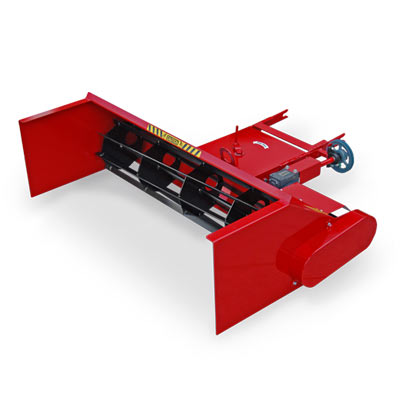

SPREAD-RITE

- Quick

- Comfortable

- Accurate to minimize shavings

- Fits:

– Steiner

– Ventrac

– Three-point hitch of compact tractor - Increased savings on labor & shavings

BLOW-RITE

- Feed conveying system to service multiple barns

from one mill location - Pipes can be buried underground to get across

driveways between barns - Airlocks driven off mill base augers or

independently with its own motor and hopper - Multiple feeders can be feed off one line

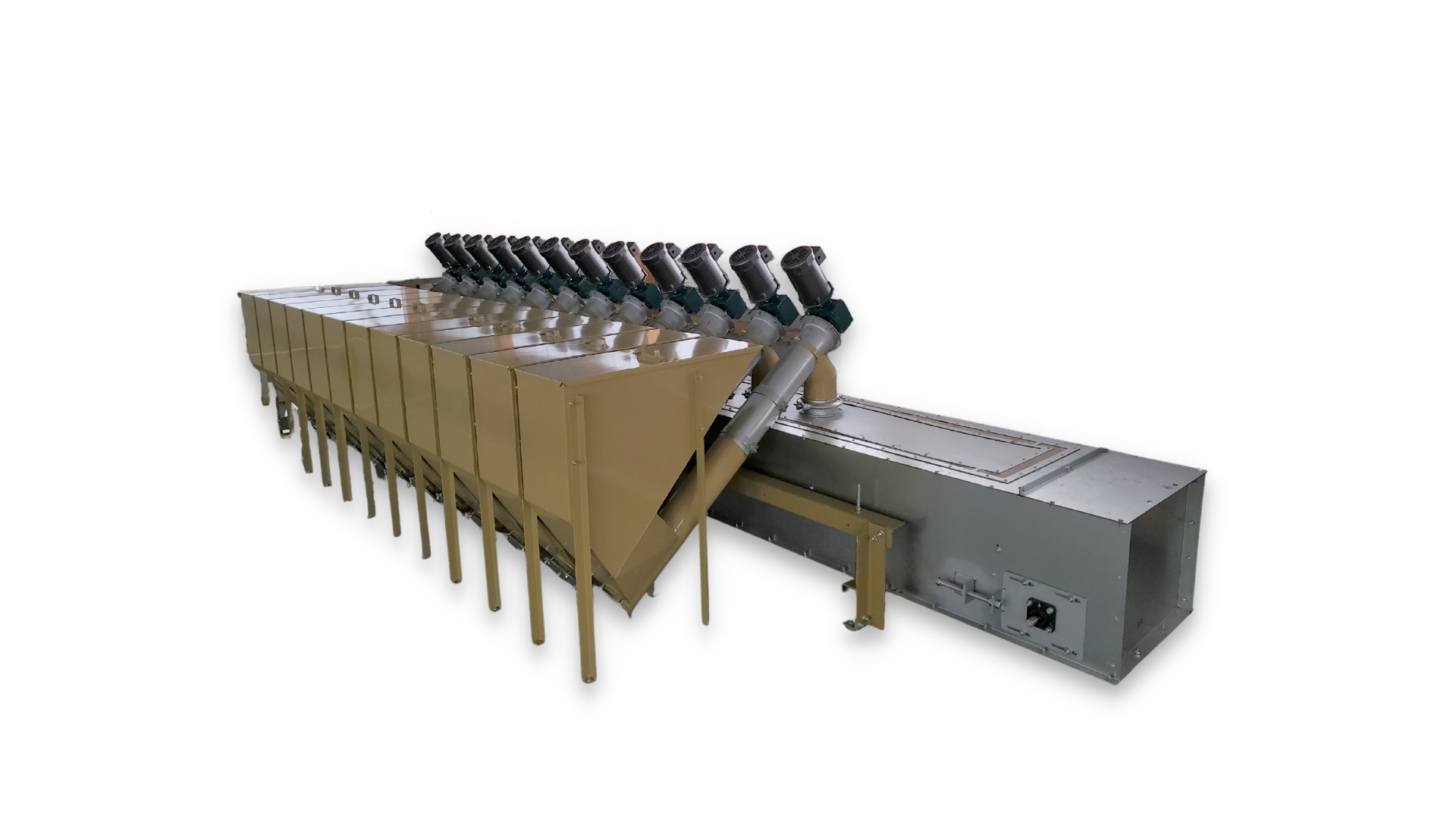

MASTER MILL BATCHING SYSTEM

- Can run up to 19 main and 19 micro ingredients

- More can be added with an upgraded license

- Can dispense up to 19 micro ingredients

- Micro ingredient conveyor has its own load cells

- Once all the micro ingredients have been collected, the conveyor adds to the batch mixer as a main ingredient

- Create any recipe, on any schedule, with any, or all of the ingredients

- Any ribbon mixer can be used with the system

- With a custom built stand, hammermills can be mounted above the mixer along with the micro ingredient conveyor and hoppers

FEED BINS

- Built to suit your needs

- Engineering that exceeds industry specifications

- Clean, smooth-walled design

- High performance industrial coating for longevity

- High-strength tubular legs

- 22” Spring loaded lid along with the micro ingredient conveyor and hoppers

We can take your farm

to the next level with our efficient feeding systems

Ask About Our Used Inventory

Testimonials

Contact Us Today

Talk to us about how Nu-Matic Systems Inc. can improve the efficiency of your farm operation. Please indicate specifically what you are inquiring about (eg. parts, sales, service, etc) in the ‘message’ field.

We will be in contact shortly.

Manufacturing Address

16 Mill Street West,

Milverton, Ontario, N0K1M0

Mailing Address

18 West Street, PO#89

Milverton, ON N0K 1M0